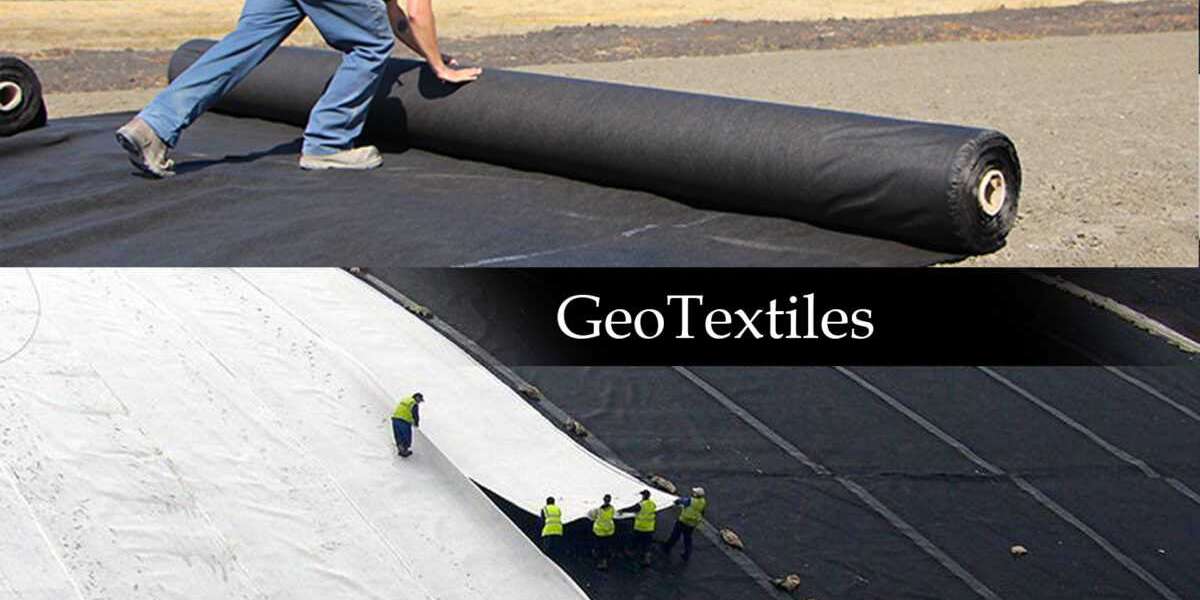

Geotextiles, a pivotal subset of geosynthetics, have become indispensable in modern civil engineering and environmental management. These permeable fabrics, manufactured from synthetic fibers, play a crucial role in various applications, including soil stabilization, erosion control, and drainage. This blog explores the different types of Geotextile fabric Price, their applications, benefits, and the future prospects of this transformative technology.

What are Geotextiles?

Geotextiles are engineered fabrics used in conjunction with soil to enhance its characteristics. These materials, typically made from polymers such as polypropylene or polyester, can be woven, non-woven, or knitted. Their primary functions include separation, filtration, reinforcement, protection, and drainage. The versatility of Geotextile fabric price in bangladesh makes them essential in a wide range of projects, from road construction to coastal protection.

Types of Geotextiles

Woven Geotextiles: These are made by weaving fibers together, creating a strong and durable fabric. They are primarily used for reinforcement and separation purposes. Their high tensile strength makes them ideal for applications where stability is critical, such as in road and railway construction.

Non-Woven Geotextiles: Produced by bonding fibers together through mechanical, chemical, or thermal processes, non-woven geotextiles are typically used for filtration and separation. They have a felt-like appearance and are used in applications where drainage and soil filtration are essential, such as in landfill liners and drainage systems.

Knitted Geotextiles: These are made by interlocking loops of yarn. While less common than woven and non-woven types, knitted geotextiles are used in specific applications requiring flexibility and high permeability.

Applications of Geotextiles

Geotextiles are used in a variety of civil engineering and environmental projects due to their ability to improve soil performance and protect the environment.

1. Road Construction

In road construction, geotextiles are used for soil stabilization and reinforcement. They help distribute loads evenly, reduce rutting, and extend the lifespan of the road. By acting as a separator between the subgrade and the aggregate, geotextiles prevent the mixing of different soil layers, which can compromise the structural integrity of the road.

2. Erosion Control

Geotextiles are instrumental in preventing soil erosion in areas prone to water runoff. They are used in conjunction with other erosion control measures, such as riprap or vegetation, to stabilize slopes and shorelines. By allowing water to pass through while retaining soil particles, geotextiles help maintain the natural landscape and prevent landslides.

3. Drainage Systems

In drainage applications, geotextiles function as filters, allowing water to pass through while preventing soil particles from clogging the drainage system. This is particularly important in retaining walls, sports fields, and agricultural fields, where efficient drainage is critical to maintaining structural integrity and preventing waterlogging.

4. Landfills

Geotextiles play a vital role in landfill management by acting as liners and covers. They prevent leachate from contaminating the groundwater and help contain waste materials. Additionally, geotextiles are used in gas venting systems to allow the escape of gases generated by decomposing waste, thereby reducing the risk of explosions.

5. Coastal and Marine Engineering

In coastal and marine engineering, geotextiles are used to protect shorelines, construct artificial reefs, and stabilize underwater soils. Their ability to withstand harsh marine environments makes them ideal for applications such as breakwaters, groins, and seawalls.

Benefits of Geotextiles

The widespread use of geotextiles can be attributed to their numerous benefits, which include:

1. Enhanced Durability

Geotextiles increase the longevity of infrastructure by improving soil stability and preventing erosion. Their ability to distribute loads and reduce stress on the underlying soil helps extend the lifespan of roads, railways, and other structures.

2. Cost-Effectiveness

By improving soil performance and reducing the need for frequent maintenance, geotextiles offer significant cost savings over the long term. Their use in construction projects can lead to reduced material costs and labor requirements.

3. Environmental Protection

Geotextiles contribute to environmental sustainability by preventing soil erosion, protecting water quality, and promoting efficient land use. Their use in landfill liners and covers helps contain waste and prevent groundwater contamination.

4. Versatility

The diverse range of geotextiles available allows for their use in a variety of applications. Whether it is road construction, erosion control, or drainage, there is a geotextile solution to meet the specific needs of each project.

5. Ease of Installation

Geotextiles are relatively easy to install, requiring minimal specialized equipment or training. This makes them accessible for a wide range of projects, from large-scale infrastructure developments to smaller, localized applications.

Future Prospects of Geotextiles

The future of geotextiles looks promising, with ongoing research and development aimed at enhancing their performance and expanding their applications. Some key trends and innovations in the geotextile industry include:

1. Sustainable Materials

As environmental concerns continue to grow, there is a significant focus on developing geotextiles made from sustainable and biodegradable materials. These eco-friendly geotextiles aim to reduce the environmental impact of construction projects and promote more sustainable land management practices.

2. Smart Geotextiles

Advancements in technology are paving the way for smart geotextiles that can monitor and respond to changes in their environment. These innovative fabrics can incorporate sensors to detect soil movement, moisture levels, and other critical parameters, providing real-time data to engineers and helping prevent structural failures.

3. Enhanced Durability and Performance

Ongoing research aims to improve the durability and performance of geotextiles, making them more resistant to environmental stresses such as UV radiation, chemical exposure, and mechanical wear. Enhanced geotextiles will offer longer service life and better performance in challenging conditions.

4. Expanded Applications

As the capabilities of geotextiles continue to evolve, their applications are expected to expand into new areas. Potential future uses include more extensive applications in renewable energy projects, such as wind and solar farms, as well as innovative solutions for urban green infrastructure and climate resilience.

5. Regulatory Support and Standards

The adoption of geotextiles is likely to be further supported by the development of standardized guidelines and regulations. Clear standards will help ensure the quality and performance of geotextiles, promoting their use in a broader range of projects and fostering greater confidence among engineers and project managers.

Conclusion

Geotextiles have revolutionized the field of civil engineering and environmental management by providing innovative solutions for soil stabilization, erosion control, and drainage. Their versatility, durability, and cost-effectiveness make them essential components of modern infrastructure projects. As research and development continue to advance, the future of Geotextile fabric price list looks bright, with exciting prospects for sustainable materials, smart technologies, and expanded applications.

Frequently Asked Questions (FAQs):

Q1: What types of geotextiles does Singhal Industries offer and what are their primary uses?

Singhal Industries provides a range of geotextiles including woven, non-woven, and knitted varieties. Woven geotextiles, known for their high tensile strength, are primarily used for reinforcement and separation in projects like road and railway construction. Non-woven geotextiles, which have a felt-like appearance, are typically utilized for filtration and separation in applications such as landfill liners and drainage systems. Knitted geotextiles, although less common, are employed in specific applications that require flexibility and high permeability.

Q2: How do Singhal Industries' geotextiles contribute to environmental protection and sustainability?

Singhal Industries' geotextiles play a significant role in environmental protection and sustainability by preventing soil erosion, protecting water quality, and promoting efficient land use. In landfill management, these geotextiles act as liners and covers to prevent leachate from contaminating groundwater and to contain waste materials. Additionally, they are used in erosion control to stabilize slopes and shorelines, thereby maintaining the natural landscape and preventing landslides. The company is also focusing on developing geotextiles made from sustainable and biodegradable materials to further reduce environmental impact.

Q3: What are the future prospects of geotextiles from Singhal Industries?

The future prospects of geotextiles from Singhal Industries are promising, with ongoing advancements aimed at enhancing performance and expanding applications. The company is investing in the development of smart geotextiles that incorporate sensors to monitor soil movement, moisture levels, and other critical parameters, providing real-time data to prevent structural failures. Research is also focused on improving the durability and performance of geotextiles to make them more resistant to environmental stresses. Moreover, Singhal Industries is exploring new applications in renewable energy projects, urban green infrastructure, and climate resilience, ensuring their geotextiles continue to meet the evolving needs of modern engineering and environmental management.