Broaching machines market was valued at US$ 296.2 million in 2022 and is expected to reach US$ 385.9 million by 2029, growing at a CAGR of 3.9% during the forecast period. Broaching is a metal removal process that utilizes long, single-point cutting tools to create precise internal and external shapes on various components.

To Know more about this report (Description, TOC and List of Tables and Figures) — Broaching Machines Market

Its high accuracy, speed, and efficiency make it a valuable tool for various industries.

Key Players:

Some leading players in the broaching machines market include:

- Nachi-Fujikoshi

- Ekin

- Mitsubishi Heavy Industries

- Forst Technologie

- Hoffmann Räumtechnik

- American Broach Machine

- Zhejiang CHR Intelligent Equipment

- The Ohio Broach Machine

- Apex Broaching Systems

- Gagan Hydraulics

- Axisco Precision Machinery

- OHTORI KIKO

- Steelmans Group

- YAO SHENG

- Stenhoj Hydraulik

- Sunny Enterprises

- YEOSHE Hydraulics

- Andy Machine Tools

Drivers and Opportunities:

Several factors are driving the growth of the broaching machine market:

- Rising demand for high-precision components: Industries like automotive, aerospace, and energy require high-precision parts, and broaching machines offer excellent accuracy and surface finish.

- Increased automation: Automation in manufacturing processes is increasing, and broaching machines are well-suited for integration into automated production lines.

- Growing adoption in emerging economies: The demand for broaching machines is increasing in developing economies like China and India due to their expanding industrial sectors.

Key opportunities in the market include:

- Development of advanced broaching tools and technologies: New materials and coatings for broaching tools, along with advancements in automation and control systems, can further improve efficiency and performance.

- Expansion into new application areas: Broaching can be used in various applications beyond traditional industries, such as medical device manufacturing and electronics assembly.

- Focus on sustainability: Manufacturers are developing energy-efficient broaching machines to reduce their environmental impact.

Segmentation by Type:

- Vertical Broaching Machine: These machines are suitable for long and slender workpieces and offer high accuracy and rigidity.

- Horizontal Broaching Machine: These machines are more versatile and can handle various workpiece shapes and sizes.

Segmentation by Application:

- Automotive: The largest application segment for broaching machines due to its high demand for precise components like gears, shafts, and engine blocks.

- Metal Fabrication: Broaching is used in various metal fabrication processes, such as gear cutting and keyway broaching.

- Energy: Broaching machines are used in the energy sector for parts like turbine blades and valves.

- Aerospace and Defense: The high-precision requirements of the aerospace and defense industries make broaching a preferred choice for critical component manufacturing.

- Others: Broaching is also used in various other industries like medical devices, electronics, and construction.

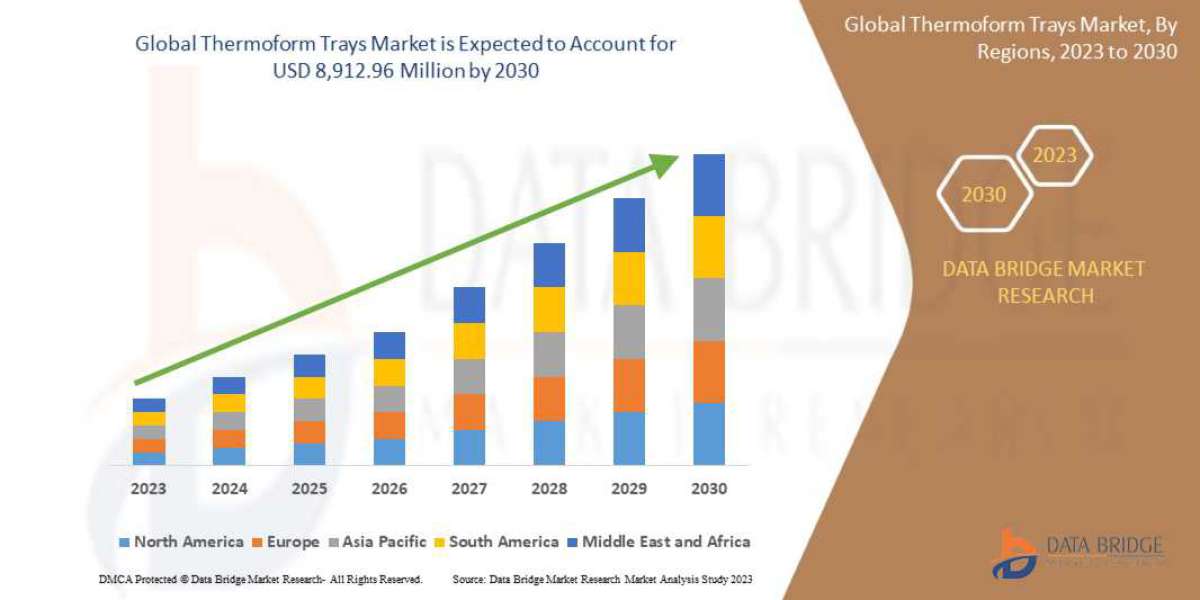

Segmentation by Region:

- North America: Holds a significant market share due to the presence of established automotive and aerospace industries.

- Europe: A mature market with strong demand from various sectors like automotive and machinery.

- Asia Pacific: The fastest-growing region due to the expanding industrial sectors in China, India, and Southeast Asia.

- South America and Middle East Africa: Smaller markets with growing potential due to increasing investments in infrastructure and manufacturing.

Overall, the broaching machine market is expected to maintain steady growth in the coming years due to increasing demand for high-precision components, automation adoption, and expansion into new application areas.

Technological advancements, sustainability focus, and penetration into emerging markets will further drive market growth. Understanding the key players, drivers, and opportunities across various segments and regions will be crucial for manufacturers and investors in navigating the market successfully.